Thermal

Qualitative

The use of experimental radiant cooling system and nature ventilation reduce the energy use in thermal control by traditional air condition. In addition, the good insulation also could reduce the energy waste in maintenance the thermal environment. Better wall, roof and glass would cost more money. However, those strategies could reduce the cost in costly HVAC system and in energy.

Better ventilation system

Located at the windward edge of campus to take full advantage of the abundant trade winds that accelerate down from the hillside above. People could control the indoor environment through the operable glass doors.

Passive: nature ventilation design

Active: fans

Ventilation System of the Building

Cooling and heating systems:

Experimental Radiant Cooling System: As an alternative to conventional air conditioning, a radiant cooling system was designed. At night water is circulated through thermal roof panels, cooled via lower evening temperatures, then stored in a below-grade tank for use as a chilled water for air handling units during warm afternoons. On the other hand, this system provides better use of water system.

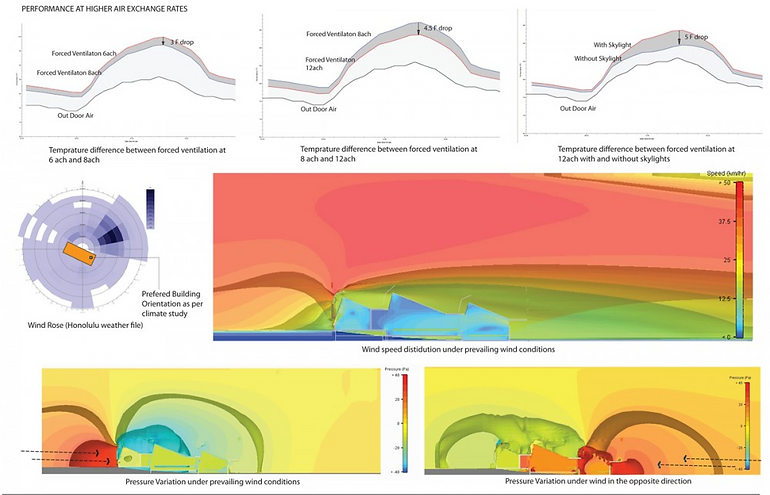

Wind Speed and Trendency of the Building

Using better materials:

Better insulation

Floor and wall tile Sonoma Tilemakers

Low radiation transmission

Glazing PPG Solarban 60 Insulated

Shading systems:

At the same time, the wood door could also provide shading, protecting indoor air temperature from increasing.

Details of Building Ventilation

Quantitative

Materials

Glazing Material of the Energy Lab

Cooler in Summer(SHGC=0.38)

The total solar energy transmitted through Solarban 60 (2)glass is almost 50% less than that transmitted by standardclear insulating glass.

• Lower SHGC numbers mean less summer heat

• Keeps interiors cooler

• Helps reduce cooling energy costs

Warmer in Winter (U-value=0.29)The winter nighttime U-value (insulating value) of Solarban 60 (2)glass is almost 50% better than standard clear insulating glass

.• Lower U-values mean higher performance

• Reduces heat furnace loss

• Helps reduce heating energy costs

WallsType:

Wood framing with batt insulation and fiber cement board and batten siding

OverallR-value R-19

Glazing Percentage North: 20%; South: 35%; East: 21%; West 30%; Skylights: 3.8%

RoofType:

Wood with rigid foam insulation and corrugated aluminum-zinc alloy coated sheet steel panels

Overall R-value: R-23

Simulation and Predict

Experimental Radiant Cooling System and Water Use

Wind Environment Simulation

Post-Occupancy Evaluation

To compare predicted energy consumption with actual results, the team carried out a post-occupancy analysis. This analysis also helped to assess the simulation software’s accuracy in determining thermal comfort and energy performance. The study used data from the building’s comprehensive metering and monitoring system, which tracks energy expenditures, weather and

thermal comfort data.

The HPA campus is located at an elevation of 2,500 ft on a leeward mountainside. Information gatheredby the BAS from the on-site weather station at five-minute intervals showed that the microclimate at the HPA campus varies significantly from the U.S. Department of Energy’s weather data for the closest site available, Hilo Airport, which is located on the coast 60 miles away at an elevation of just 38 ft.

The average predicted temperature and relative humidity (RH) were higher than the actual (meaning that the actual conditions were more favorable). The average predicted temperature was 73.6°F, and the average actual temperature was 65.1°F; the average predicted RH was 79.6%, and the actual RH average was 76.7%.

In addition, the actual solar radiation was higher than estimated, resulting in more electricityproduction. On average, the wind speeds were significantly lower than estimated, meaning that the windows could be left open with less risk of excessive wind speed conditions, reducing the need for active systems.

Wind Speed Comparison

Energy Use Comparison of Cooling System